About ION Enterprises

Founded in 1990 in England, ION Enterprises manufacturers a range of environmental water treatment devices under the trademark ION ScaleBuster®. The company has sales offices in Europe, North, Central and South America, the Middle East and Asia. Since inception, ION ScaleBuster products have been installed, with excellent results, in more than 300,000 applications for commercial, industrial, municipal and residential projects around the world.

ION ScaleBuster technology is used around the world by major companies and institutions for its proven ability to inhibit scale and corrosion. In the process, they are saving energy and water, and minimizing the use chemicals in their cooling and production systems.

Here are just a few of the firms putting ScaleBuster to use in their operations:

- ABB

- Alstom GmbH

- Bayer AG

- Daewoo Korea

- Hyundai Korea

- Thyssen Krupp Nirosta AG

- Life Technologies (multiple locations, USA)

- Messe Düsseldorf GmbH

- Municipal Buildings (AZ, CA, TX, ON)

- Hotel Adlon Berlin

- Savoy Hotel London

- The Ontario Green Schools (Canada)

- University College London

- University of London

- Naval Medical Facilities USA

- VA Hospitals across USA

- Pepsi Cola (multiple Plants Worldwide)

- Republic National Bank of New York

- Canada Square London (UK)

- Sheraton

- Doubletree Hotel

- Marks & Spencer

- Ontario Ministry of the Environment Toronto

- Ministry of Defense of the UK (H.M.S.)

- Police Departments (USA, UK)

- CFIA (Canadian Food Inspection Agency)

- NASA (several facilities USA)

It future

The Problem

Scale and general corrosion form on equipment surfaces and restrict water flow, clog systems and reduce system efficiency resulting in costly equipment down time and increased maintenance costs. Using chemicals to treat these conditions results in high chemical disposal costs, pollution of the environment and related health and safety issues. With new regulations limiting salt usage and disposal, most traditional ion-exchange softeners have more cons than pros. Membrane technology has high CapEx as well as OpEx, with a lot of wasted water (up to 25-30% in some cases) making it both costly and unfriendly to the environment. Many customers have found that their hardness-free water can be easily replaced by treating the hard water with a physical system reducing the hardness drastically without the costly membranes or the polluted salt.

The Solution

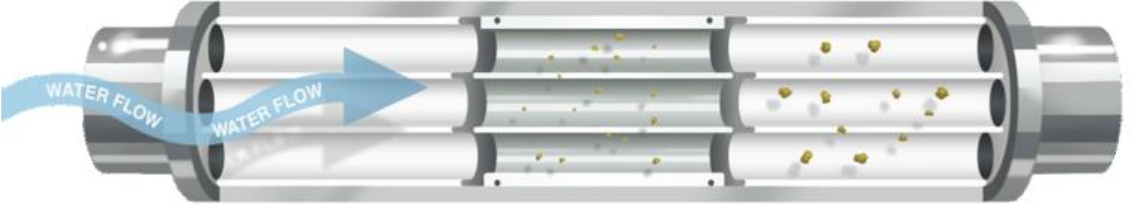

The basic function of the ION ScaleBuster as a physical water conditioner is to inhibit and prevent scale in water systems. The patented electrostatic conditioner operates without any electrical power and has no moving components. The electrostatic device uses the dielectric characteristics of the materials of its construction combined with the hydraulic conditions present during operation to force the precipitation of solid crystals in the water. This prevents scale from forming and allows precipitation of hardness ions (as Ca++ and Mg++). The unique ISB Hardness Reduction System physically removes the precipitated hardness ions (or scale) from the water. This system is installed as a side-stream to a storage tank allowing supply of hardness-reduced water (as the old fashioned ion-exchange softeners used to, but without the needed harsh salt regeneration, eliminating the disposal of that salt either as brine or as slush after drying).

Here is a simple and easy to operate

salt-free, chemical-free

ISB Hardness Reduction System with the ScaleBuster® technology

- As water flows through, cavitation within the ION ScaleBuster chamber unit produces violent pressure changes that break up bicarbonate molecules and the dielectric materials produce static effects.

- The galvanizing action of the ION ScaleBuster causes the breakdown of calcium and magnesium bicarbonates in the solution, (hardness in the water) which precipitate less soluble carbonates.

- As a result, the treated water becomes less saturated and is able to dissolve existing deposits over time.

- The combination of these effects is repeated many times. Once the salts are precipitated or removed, this action improves the flow and overall efficacy and efficiency of the piping system.

The High Cost of Corrosion & Scale Fouling

Equipment Damage, Energy Loss, & Increased Maintenance

The formation of scale and corrosion on equipment surfaces restricts water flow, clogs equipment and reduces system efficiency. The results can be costly — increased energy consumption, greater downtime, and additional maintenance and reduced equipment life.

Energy Savings

Because the ION ScaleBuster removes existing scale buildup on pipework, valves, heating elements including hot water heaters, electrical heating elements, industrial heat exchangers, hot water pipes and tanks, less energy is required to heat the water.

Clears Existing Scale Deposits

The galvanic effect of the ION ScaleBuster provides a reducing effect on corrosion sites. By precipitating hardness, the treated water becomes less saturated and, therefore, is able to dissolve old deposits over a period of time.

The time taken will depend on several factors—the thickness of scale deposits and the distance of effected area from the installed ION ScaleBuster. The volume of water passing through ION ScaleBuster will determine the length of time taken to clean scale and corrosion deposits from the system. However, once installed, a ScaleBuster unit will commence its job immediately provided that a water flow is still possible.

Safe, Chemical-Free Operation

A Safe, Environmentally-Friendly Process

Unlike systems that use harsh chemicals to dissolve scale and corrosion and contribute toxic pollutants to groundwater, the ION ScaleBuster works without chemicals. Instead, it employs an electrostatic process that is planet-friendly. This reduces energy and water consumption, while reducing or, in certain cases, eliminating toxic water discharge.

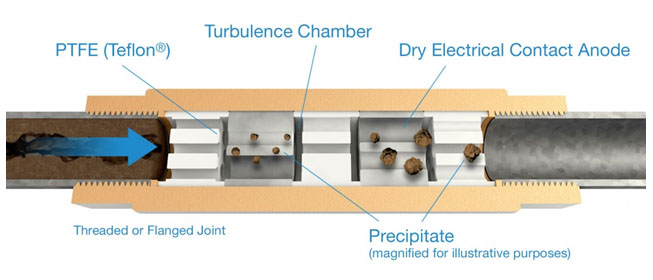

Chemical-Free Flocculant

The patented construction of its PTFE (Teflon®) turbulence chambers alters the static balance within the unit. This neutralizes charged particles, causing them to flocculate, or form large clump particles that are slower to re-dissolve in the water.

In normal “straight flow” systems, the flocculate particles of scale remain harmlessly in the flow of the water and are unable to adhere to the pipe surfaces. In re-circulating systems – or those that contain settlement areas – filtration or flushing is commonly used to remove these treatment by-products.

Corrosion is now under control and further damage to the system and associated equipment is prevented.

Water Savings

Environmental Responsibility

Energy Conservation

EnviroTower™ Water Treatment System

How it works

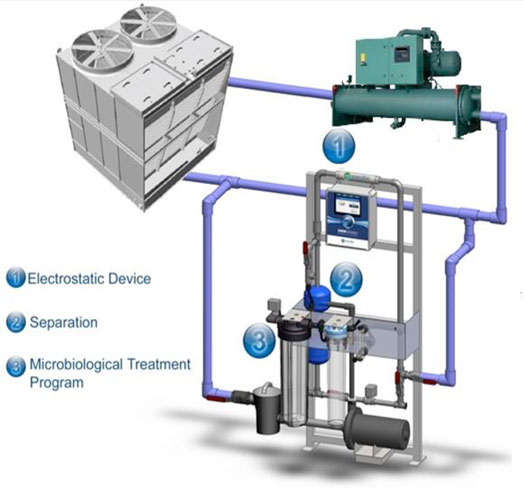

The patented EnviroTower – the Cooling Tower Water Treatment solution is designed around the ScaleBuster conditioner which precipitates the hardness in the cooling water, causing those ions to build clusters which grow larger as the water is recirculating through the ScaleBuster conditioner of the EnviroTower system, until they are removed from the water by the separation process.

The EnviroTower system is monitoring the cooling system’s water conductivity and controls the blow down allowing for Cycling up, saving water, while keeping the system scale-free.

In a period of 30 minutes after dosing any chemical – the EnviroTower system avoids any blow down to eliminate drainage of the chemicals before they have actually performed in the water.

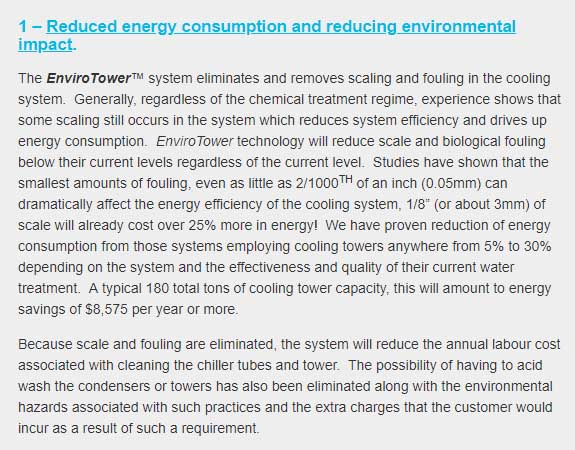

The EnviroTower cooling tower water treatment solution optimizes energy and water efficiencies while minimizing environmental impacts. Cooling towers represent up to 30% of a building’s overall energy budget, and 50% of the water used. The EnviroTower solution helps commercial, institutional and industrial facilities significantly reduce their cooling costs. The patented, comprehensive water treatment solutions have earned endorsement of North America’s largest and most demanding organizations through its ability to deliver consistent, reliable results.

- Electrostatic water conditioner — The patented ScaleBuster® technology that pre-emptively precipitates solids and acts to prevent scale in equipment surfaces and control potential corrosion.

- Separation — Captures and discharges precipitated solids created by the electrostatic device, keeping the water as clean as possible.

- Microbiological treatment program — Supplementary treatment program to control microbiological activity and corrosion in the system.

Benefits of the EnviroTower™ technology as a Cooling Tower Water Treatment solution

Unlike systems that use harsh chemicals to dissolve scale and corrosion and contribute toxic pollutants to groundwater, the ION ScaleBuster works without chemicals. Instead, it employs an electrostatic process that is planet-friendly. This reduces energy and water consumption, while reducing or, in certain cases, eliminating toxic water discharge.